PUSH-PULL & STRAIGHT-LINE Manual Toggle Clamps

-

Product NameQtyPriceSubtotal

-

R.M.T. - Ridiculous Machine Tools

300LB 5/16-18 THRD BDY STRAIGHT LINE CLAMP Machinist Choice

Qty :Price :$35.16$16.43Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

700LB 3/8-16 THRD BDY STRAIGHT LINE CLAMP Machinist Choice

Qty :Price :$53.97$26.85Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

2500LB FLG BASE STRAIGHT LINE CLAMP METRIC THREAD Machinist Choice

Qty :Price :$60.50$31.63Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

400LB 5/16-18 FLG BASE STRAIGHT LINE CLAMP Machinist Choice

Qty :Price :$38.72$15.97Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

300LB 5/16-18 THRD BDY STRAIGHT LINE CLAMP STAINLESS STEEL Machinist Choice

Qty :Price :$67.74$42.39Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

300LB FLG BASE STRAIGHT LINE CLAMP Machinist Choice

Qty :Price :$37.69$15.25Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

100LB FLG BASE STRAIGHT LINE CLAMP Machinist Choice

Qty :Price :$21.52$8.70Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

700LB 5/16-18 FLG BASE STRAIGHT LINE CLAMP Machinist Choice

Qty :Price :$51.11$25.93Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

850LB M10 P=1.5 FLG BASE STRAIGHT LINE CLAMP METRIC THREAD Machinist Choice

Qty :Price :$44.73$20.05Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

800LB FLG BASE STRAIGHT LINE CLAMP Machinist Choice

Qty :Price :$49.28$23.40Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

200LB 1/4-20 THRD BODY STRAIGHT LINE CLAMP Machinist Choice

Qty :Price :$29.30$13.04Subtotal : $0.00

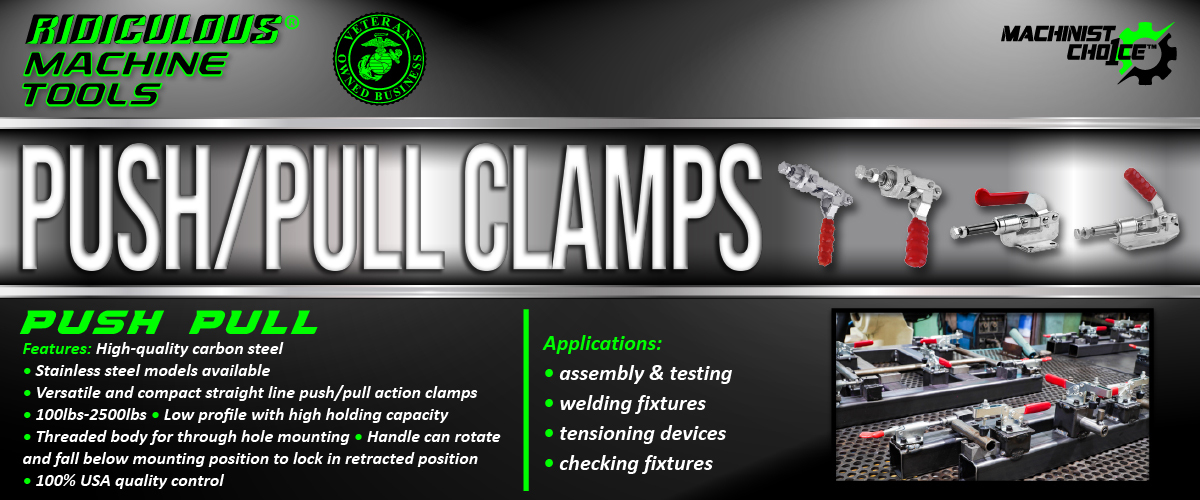

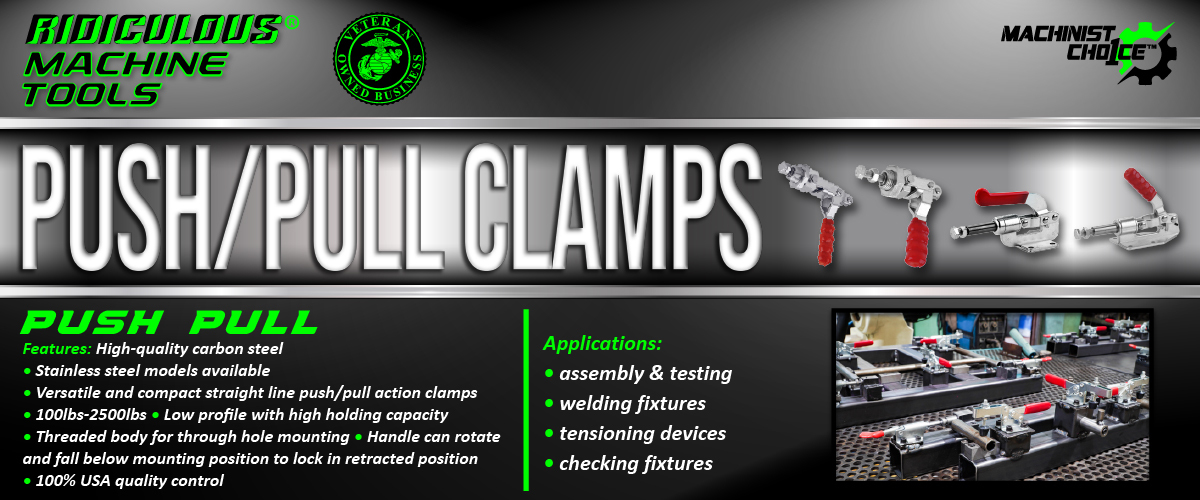

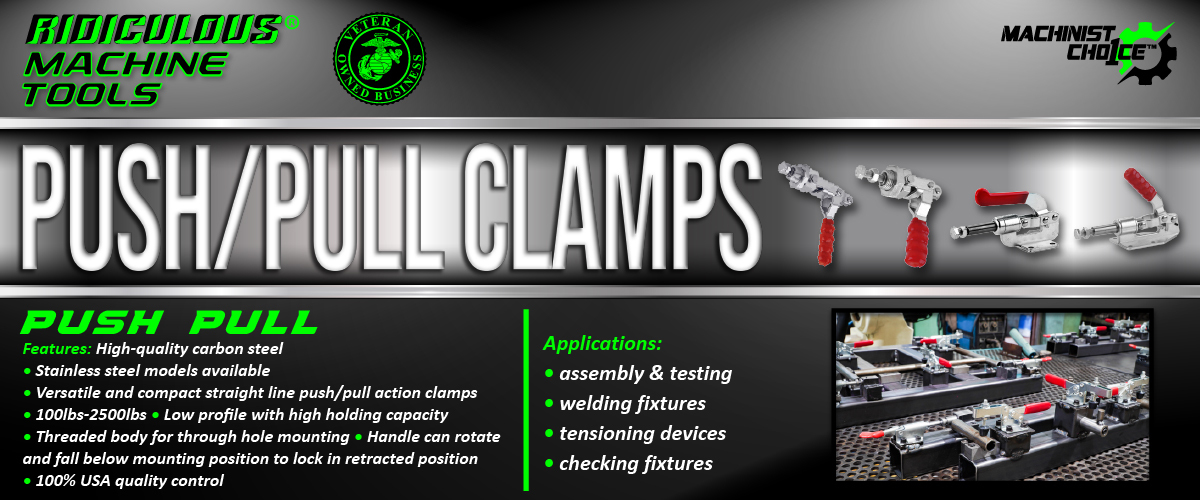

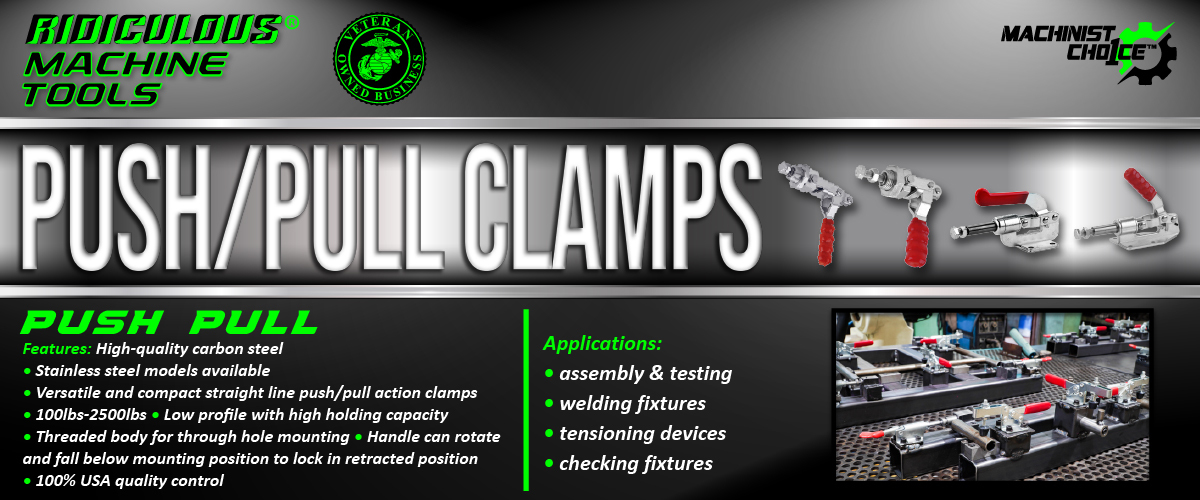

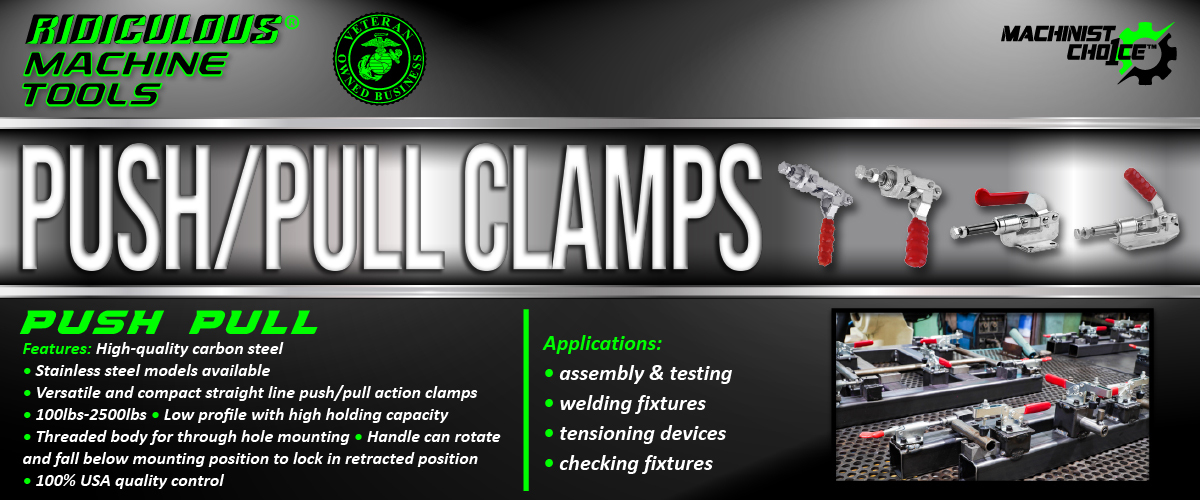

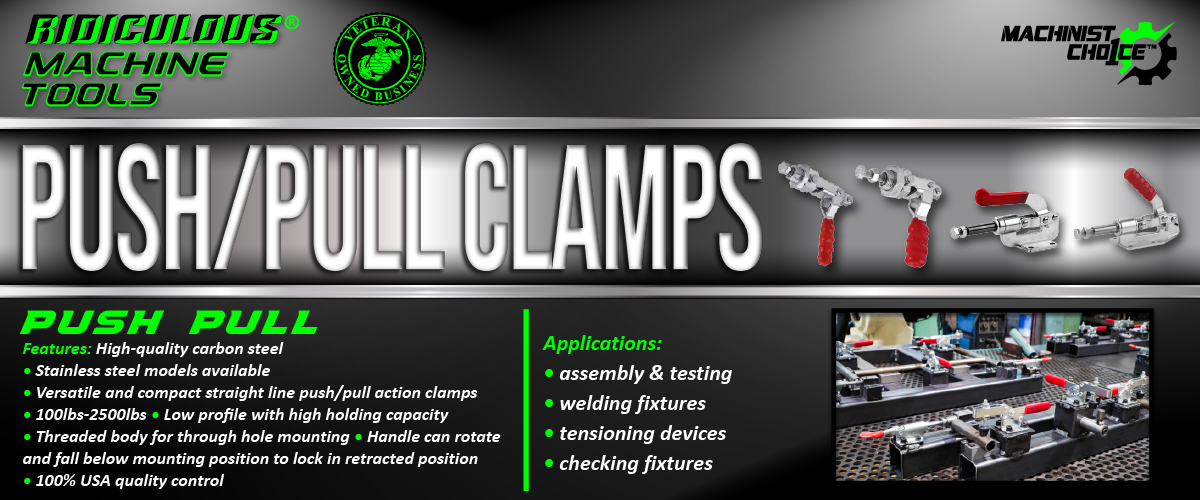

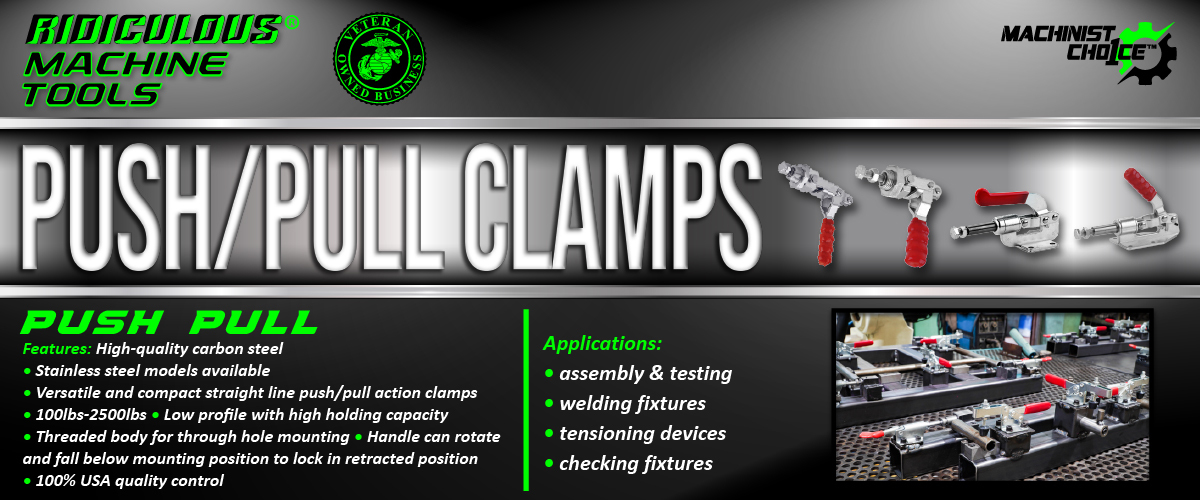

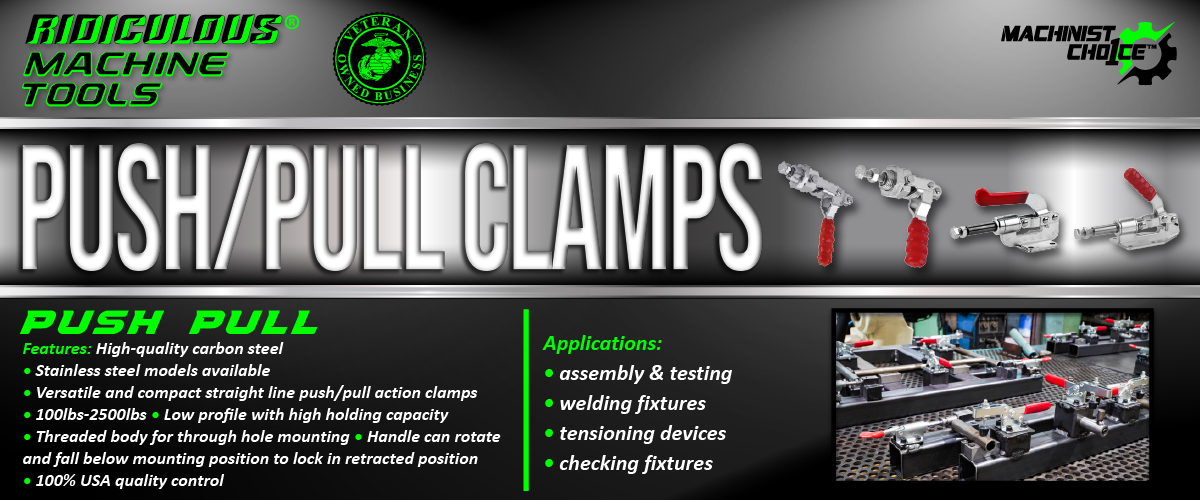

Push-Pull and Straight-Line Toggle Clamps: Precision Tools for Industry

Ridiculous Machine Tools is a leading manufacturers of precision clamping solutions, we take pride in offering an extensive range of Push-Pull Toggle and Straight-Line Toggle Clamps. Our clamps are engineered with the highest standards of quality and versatility, serving a broad spectrum of industrial and manufacturing applications. These precision tools are indispensable in securing workpieces firmly in their desired position, thereby facilitating meticulous operations across welding, cutting, assembly, and inspection processes

Show MoreThe general use of a push-pull toggle clamp involves securing or holding workpieces in a fixed position for various operations such as welding, machining, assembly, and inspection. The user engages the clamp by operating a handle that activates a straight-line, push-pull action, exerting a clamping force directly onto the workpiece in any direction needed. This action can either push components together or pull them against a supporting fixture, depending on the setup.

Show MoreThe straight-line toggle clamp's design is often more straightforward, focusing on the efficient transmission of force in a singular direction. This simplicity can translate to higher clamping efficiency and reliability in applications that demand precise force application without the need for adjustment in the direction of force. Straight-line toggle clamps excel in situations where a uniform, direct force is essential for holding parts without any shift or tilt.

Show MorePush Pull Toggle Clamps in Precision Machining

In the realm of precision machining, the significance of reliable and effective clamping solutions cannot be overstated. Push Pull Toggle Clamps have emerged as a vital tool in this arena, offering numerous benefits and advantages that directly impact the efficiency and accuracy of machining operations. This article delves into how these clamps play a pivotal role in precision machining and the myriad of benefits they offer to machinists.

Show MoreUnlocking Efficiency in Woodworking with Puch-Pull Toggle Clamps

In the diverse world of woodworking, where precision and versatility meet the ruggedness of natural materials, push-pull toggle clamps emerge as invaluable tools for craftsmen and hobbyists alike. These clamps excel in offering adjustable, secure holding solutions that cater to the dynamic needs of woodworking projects, from delicate joinery to robust furniture assembly. Their unique ability to apply force in both pushing and pulling directions allows for unparalleled flexibility in workpiece positioning and securing, making them an essential component in achieving flawless results. Whether you're meticulously shaping a custom piece or swiftly moving through production runs, push-pull toggle clamps enhance your workflow, ensuring that every cut, carve, and join is executed with precision and efficiency in the woodworking industry.

Show MorePush-Pull Toggle Clamps in Welding and Fabrication

In the demanding world of welding and fabrication, precision, and efficiency are not just goals but necessities. Push Pull Toggle Clamps have become an invaluable asset in these industries, offering a combination of strength, stability, and versatility. This article delves into the numerous benefits and features of Push Pull Toggle Clamps, underscoring their importance in welding and fabricating applications.

Show MoreFrequently Asked Questions

-

1. What is the difference between a Push-Pull and a Straight Line Toggle Clamp?

The primary difference between push-pull and straight-line toggle clamps lies in their mechanism of action and applications. Push-pull toggle clamps are designed to either push or pull a workpiece towards or away from a point of reference, offering versatility in the direction of applied force. They are ideal for scenarios where the workpiece needs flexible positioning or securing but may require quick release and re-securing in a different orientation. On the other hand, straight-line toggle clamps exert force in a direct, linear path from the clamp towards the work surface, making them suitable for applications that demand a strong, steady downward force without lateral movement. Straight-line clamps are preferred for operations needing uniform pressure application and utmost workpiece stability. Essentially, the choice between the two depends on the specific needs of your project, particularly regarding the direction and nature of the force required.

-

2. Do you make Push-Pull or Straight-Line Toggle Clamps that are currently not available or showing this website?

Yes... We can make any clamp that you need. Usually, we need a minimum order quantity of 500 pieces but if your request has been submitted previously by another customer we would consider adding the clamps to our offering Please contact us InfoQuotes@ridiculousmachinetools.com to receive your quote.

-

3.How do I choose the right Push-Pull or Straight-Line toggle clamp for my application?

When selecting the correct Push-Pull or Straight-Line toggle clamp, consider factors such as the clamping force required, the size and shape of the workpiece, and the space available for mounting. It's essential to match the clamp's capacity and reach the specific requirements of your machining project.

-

4.What features should I look for in a high-quality Push-Pull or Straight-Line toggle clamp?

Look for Push-Pull or Straight-Line toggle clamps with sturdy construction, durable materials, and ergonomic handle designs for ease of use. Features such as adjustable clamping pressure, quick-release mechanisms, and anti-slip grips can enhance the functionality and performance of the clamp. You always want to purchase from a reputable manufacturer like Ridiculous Machine Tools that has the expertise and knowledge needed to produce high quality clamps.

-

5. How can I ensure proper maintenance and care for my Push-Pull or Straight-Line toggle clamps?

To maintain the effectiveness of your Push-Pull or Straight-Line toggle clamps, regularly inspect them for signs of wear, damage, or misalignment. Keep the clamping surfaces clean and free from debris, and lubricate moving parts as recommended by the manufacturer to ensure smooth operation.

-

6.Can Push-Pull or Straight-Line toggle clamps be customized to meet specific machining needs?

Yes, Ridiculous Machine Tools offer customization options for Push-Pull or Straight-Line toggle clamps, including variations in handle styles, clamping capacities, and mounting configurations. Customized solutions can be tailored to accommodate unique workpiece shapes, sizes, and material requirements for specialized machining applications.