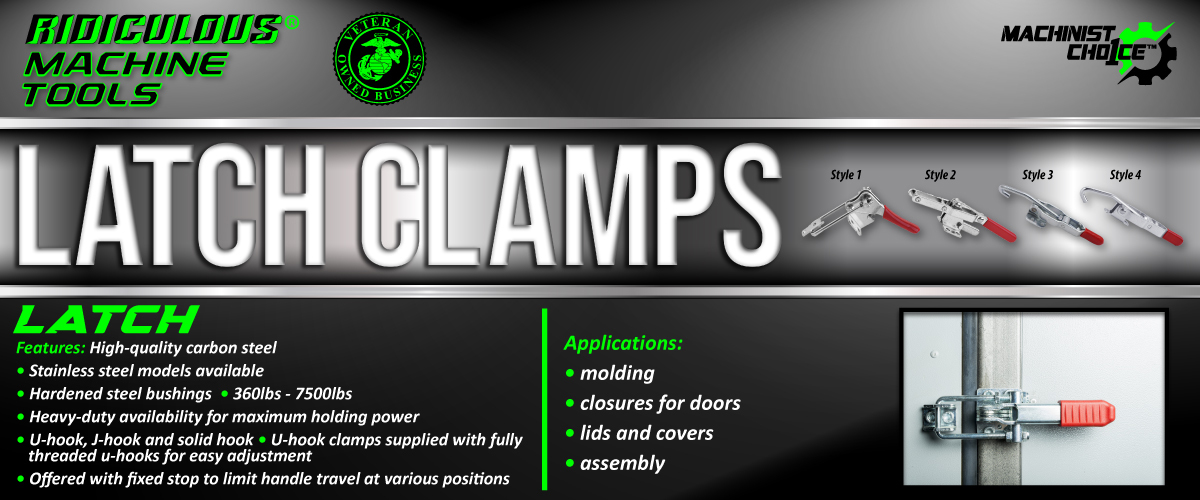

LATCH Manual Toggle Clamps

-

Product NameQtyPriceSubtotal

-

R.M.T. - Ridiculous Machine Tools

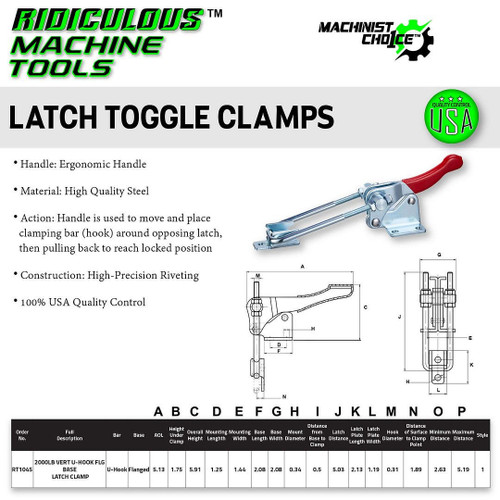

2000LB U-HOOK FLG BASE LATCH CLAMP Machinist Choice

Qty :Price :$42.72$18.58Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

4000LB U-HOOK FLG BASE LATCH CLAMP WITHOUT LATCH PLATE Machinist Choice

Qty :Price :$70.47$38.94Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

375LB J-HOOK NARROW BASE LATCH CLAMP Machinist Choice

Qty :Price :$29.85$12.77Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

2000LB U-HOOK FLG BASE LATCH CLAMP STAINLESS STEEL Machinist Choice

Qty :Price :$76.05$43.03Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

700LB U-HOOK FLG BASE LATCH CLAMP Machinist Choice

Qty :Price :$28.93$11.49Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

700LB U-HOOK FLG BASE LATCH CLAMP STAINLESS STEEL Machinist Choice

Qty :Price :$42.86$21.74Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

2000LB VERTICAL U-HOOK FLG BASE LATCH CLAMP Machinist Choice

Qty :Price :$46.68$21.47Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

360LB U-HOOK FLG BASE LATCH CLAMP STAINLESS STEEL Machinist Choice

Qty :Price :$30.43$15.23Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

500LB VERTICAL U-HOOK FLG BASE LATCH CLAMP STAINLESS STEEL Machinist Choice

Qty :Price :$41.69$22.14Subtotal : $0.00

Latch Toggle Clamps: Hook and Latch Clamps for Industry

As a leading manufacturer of latch and hook toggle clamps, we pride ourselves on offering tools that are not just something you use in a shop but solutions to the challenges faced in manufacturing, construction, and industrial applications. Our latch toggle clamps are engineered for unparalleled precision, reliability, and efficiency, making them indispensable across a broad spectrum of industries. Here, we'll delve into the versatile world of our clamps, exploring their uses, benefits, and the mechanical ingenuity that makes them a must-have in your toolkit.

Show MoreThe toggle mechanism within the clamp is what allows it to apply a significant amount of clamping force with minimal effort from the user. Once the clamp is in the locked position, the toggle mechanism ensures a secure hold, preventing accidental release. The clamp remains locked until the handle is manually disengaged, releasing the tension and allowing the clamped pieces to be separated.

Show MoreThe core design elements of a hook style latch clamp include a handle, a base, a movable hook, and a latch plate or eye. The operational mechanism is straightforward yet effective: as the handle is activated, it drives the hook to catch onto a latch plate or eyelet attached to the opposing component. This mechanism draws the two parts together, securing them in place. The toggle action ensures that once the hook is engaged and the clamp locked, a strong and reliable hold is maintained, preventing accidental disengagement until the handle is manually released.

Show More1. Injection Molding: In the injection molding industry, hook and latch toggle clamps are crucial for holding mold halves together during the molding process. Their ability to apply a strong and consistent clamping force ensures that the mold remains closed under high pressure, resulting in precise and accurate moldings.

2. Manufacturing and Assembly: These clamps are widely used in the manufacturing sector to secure components during assembly. This is particularly important in the production of complex machinery and equipment, where precise alignment and secure fastening of parts are critical to the functionality and safety of the final product.

3. Automotive: In automotive manufacturing and repair, hook and latch toggle clamps are used to secure body panels, doors, and other components during assembly and maintenance. Their robust design ensures a secure hold, which is essential for tasks requiring precision and durability.

Show MoreUnderstanding Hook and Latch Toggle Clamps: U-Bolt and J-Hook Varieties

Hook and latch toggle clamps are engineered for precision and reliability, designed to pull and secure components together efficiently. These clamps are available in two primary configurations, each tailored to specific application needs: the U-Bolt and J-Hook latch toggle clamps. Each type brings unique benefits to various clamping and assembly tasks.

Show MoreLatch toggle clamps operate on a simple yet effective mechanical principle that allows them to apply a secure and consistent clamping force to hold two objects together. These tools leverage the mechanics of levers and pivots to transform a manual input force into a significant clamping force. Understanding the mechanical aspects of latch toggle clamps involves exploring their design, components, and the principle of operation.

Show MoreFrequently Asked Questions

-

1. Do you make Latch Toggle Clamps that are currently not available or showing this website?

Yes... We can make any clamp that you need. Usually, we need a minimum order quantity of 500 pieces but if your request has been submitted previously by another customer we would consider adding the clamps to our offering Please contact us InfoQuotes@ridiculousmachinetools.com to receive your quote.

-

2. How do I choose the right Latch toggle clamp for my application?

When selecting the correct Latch toggle clamp, consider factors such as the clamping force required, the size and shape of the workpiece, and the space available for mounting. It's essential to match the clamp's capacity and reach the specific requirements of your machining project.

-

3.What features should I look for in a high-quality Latch toggle clamp?

Look for Latch toggle clamps with sturdy construction, durable materials, and ergonomic handle designs for ease of use. Features such as adjustable clamping pressure, quick-release mechanisms, and anti-slip grips can enhance the functionality and performance of the clamp. You always want to purchase from a reputable manufacturer like Ridiculous Machine Tools that has the expertise and knowledge needed to produce high quality clamps.

-

4.How can I ensure proper maintenance and care for my Latch toggle clamps?

To maintain the effectiveness of your toggle latches clamps, regularly inspect them for signs of wear, damage, or misalignment. Keep the clamping surfaces clean and free from debris and lubricate moving parts as recommended by the manufacturer to ensure smooth operation.

-

5. What is a latch toggle clamp?

A latch toggle clamp is a fastening device used to securely hold two components together. It features a handle for operation, a clamping arm that moves in a latching motion, and a base for mounting. These clamps are widely used in manufacturing, woodworking, and metalworking for their strong holding capacity.

-

6.How do I use a latch toggle clamp?

To use a latch toggle clamp, position the clamp so the latch arm or hook can reach the mating component or catch. Press down on the handle to move the arm into a closed position, securing the components together. The toggle mechanism locks the clamp in place until the handle is lifted to release.

-

7.What are the differences between U-Bolt, J-Hook, and Solid Bar latch toggle clamps?

U-Bolt clamps are versatile for round or irregular shapes, providing a U-shaped bolt to encircle the workpiece. J latch clamps feature a hook-shaped arm, ideal for grasping and pulling components together. Solid Bar clamps use a solid bar for straightforward, heavy-duty clamping, offering robustness and simplicity.

-

8.Can latch toggle clamps be adjusted for different sizes or thicknesses?

Yes, many latch toggle clamps, especially U-Bolt and Solid Bar types, feature adjustable mechanisms that allow you to modify the clamping distance or force to accommodate various sizes or thicknesses of workpieces.

-

9.Are latch toggle clamps suitable for heavy-duty applications?

Absolutely. Heavy duty toggle latch clamps, particularly those with solid bars, are designed for heavy-duty use. Their robust construction and strong clamping force make them ideal for applications requiring substantial holding power.

-

10.Can latch toggle clamps be used in welding applications?

Yes, latch toggle clamps can be used in welding applications. They are particularly useful for holding metal pieces together before and during welding. It's important to choose clamps made from materials that can withstand the heat and spatter associated with welding.

-

11. Are latch toggle clamps effective for securing workpieces on CNC machines?

Yes, latch toggle clamps can be effectively used to secure workpieces on CNC machines, ensuring they remain stationary during the machining process. Their quick-release mechanism also allows for efficient workpiece changes.