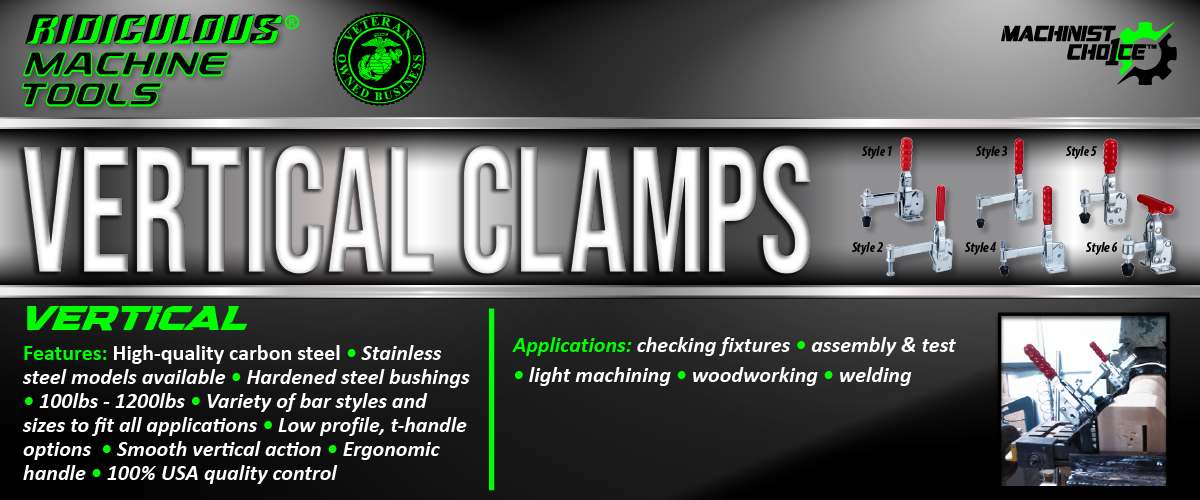

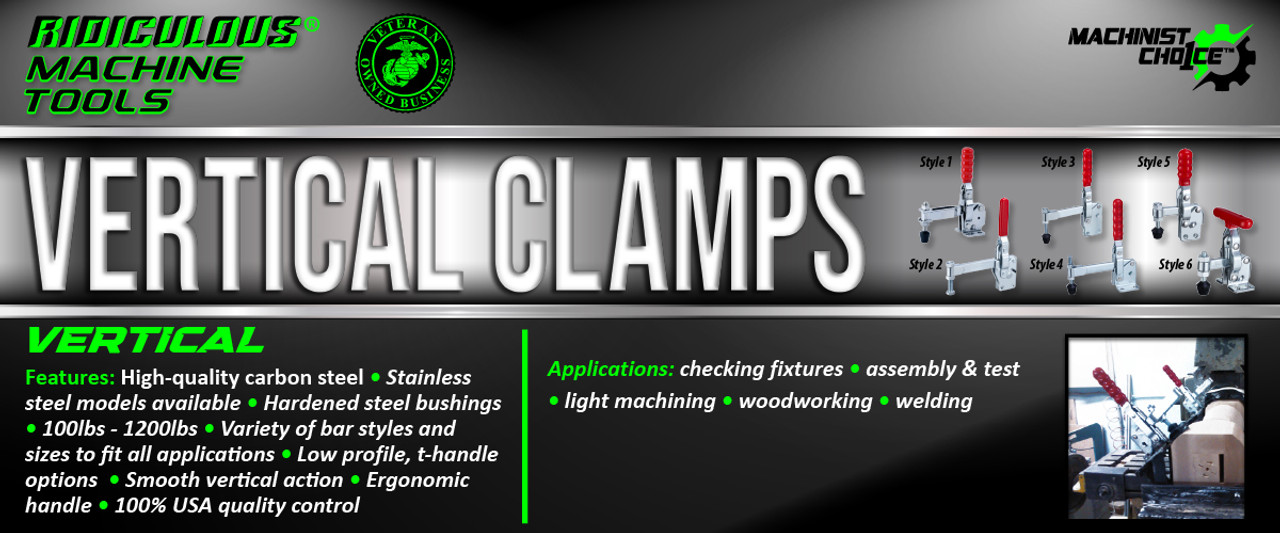

Manual VERTICAL Toggle Clamps

-

Product NameQtyPriceSubtotal

-

R.M.T. - Ridiculous Machine Tools

200LB FIXED SPINDLE STRAIGHT HANDLE VERTICAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$34.89$12.83Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

500LB U-BAR FLG BASE VERTICAL HOLD-DOWN CLAMP STAINLESS STEEL Machinist Choice

Qty :Price :$57.13$29.15Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

100LB U-BAR FLG BASE VERTICAL HOLD-DOWN CLAMP STAINLESS STEEL Machinist Choice

Qty :Price :$38.65$18.22Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

1000LB U-BAR STRAIGHT BASE VERTICAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$55.73$28.14Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

1000LB U-BAR FLG BASE VERTICAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$55.73$28.14Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

750LB U-BAR FLG BASE VERTICAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$43.34$19.04Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

500LB U-BAR FLG BASE VERTICAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$37.58$14.81Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

500LB U-BAR STGHT BASE VERTICAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$37.58$14.81Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

500LB LONG U-BAR FLG BASE VERTICAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$37.58$14.81Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

750LB SOLID BAR FLG BASE VERTICAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$44.59$19.96Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

750LB U-BAR STGHT BASE VERTICAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$43.67$19.27Subtotal : $0.00

A vertical toggle clamp is identified by the orientation of its handle when the clamp is in its fully engaged, locked, or closed state. Unlike its horizontal counterpart, the handle of a vertical toggle clamp stands upright in a vertical plane perpendicular to the base or the surface it's mounted on when the clamp is locked.

The vertical orientation during engagement means that to operate the clamp, you will typically pull the handle upwards or push it downwards, moving it through a vertical arc. Once the clamp is fully engaged and the mechanism is locked, the handle will be positioned upwards, pointing away from the workpiece. This characteristic is especially advantageous in workspaces where horizontal space around the workpiece is constrained, as it allows the handle to occupy minimal space laterally.

Show MoreFrequently Asked Questions

-

1. What is the difference between a Vertical and a Horizontal Toggle Clamps?

The key distinction between vertical and horizontal toggle clamps lies in the orientation of their handles during the clamp's engagement or locking phase. With vertical toggle clamps, the handle stands upright, perpendicular to the mounting surface, when the clamp is fully engaged or in its locked position. Conversely, horizontal toggle clamps feature a handle that aligns parallel to the mounting surface, lying flat when the clamp is securely locked.

This fundamental difference in design directly influences the clamp's application based on the spatial constraints and requirements of your project. For setups where vertical space is limited, horizontal toggle clamps offer a low-profile solution, keeping work areas clear and accessible. Alternatively, in scenarios where lateral space around the workpiece is constrained, vertical hold-down toggle clamps provide an effective clamping solution without extending into the workspace.

Choosing between vertical and horizontal toggle clamps depends on the specific needs of your workpiece and the configuration of your machinery or fixture. At RMT we recommend assessing both your spatial limitations and the demands of your project to select the most appropriate toggle clamp orientation, ensuring optimal performance and efficiency in your clamping operations.

-

2. What is the purpose of vertical toggle clamps in machining?

Vertical toggle clamps are used to secure workpieces in machining operations, increasing efficiency and precision in the process.

-

3. What are the benefits of using vertical toggle clamps in machining?

The benefits include elevated efficiency, improved precision, user-friendly design, and versatility.

-

4. How can I choose the right vertical toggle clamps for my machining process?

Consider factors such as the size and shape of the workpiece, the type of machining operation, and the clamp's capacity when choosing the appropriate vertical toggle clamps. Select clamps that meet specific needs and requirements for maximum efficiency and precision. The manufacturer should be able to help you with your application. Sometimes it’s a good idea to ask as maybe someone already created that wheel. You never know

-

5. What makes vertical handle toggle clamps suitable for machining operations?

Vertical toggle clamps are designed to provide stability and precision during machining operations. They feature a sturdy, user-friendly design that allows for easy and efficient clamping of workpieces. Additionally, their versatility in a range of operations, including drilling, milling, and grinding, makes them a valuable tool for streamlining the production line.

-

6. Are vertical toggle clamps suitable for both small workshops and large industrial facilities?

Yes, vertical toggle clamps can be tailored to meet the specific needs and requirements of both small workshops and large industrial facilities. Whether you're a small operation or a large-scale facility, these clamps can provide stability and precision in machining operations, helping you to maximize efficiency and enhance performance.