Maximizing CNC Efficiency with the Best Tool Holder Selection

Posted by SRMT on Apr 13th 2024

Introduction to CNC Efficiency and Its Importance

CNC, short for Computer Numerical Control, revolutionizes how we manufacture parts, from tiny screws to massive airplane components. The heart of maximizing CNC efficiency lies in the seemingly small detail of selecting the right tool holder. Think of the CNC machine like a prize-winning racehorse; no matter how strong or fast it is, the wrong shoes can drastically slow it down. Similarly, picking the optimal tool holder not only ensures the machine works at its best but also extends the lifespan of both the tools and the machine itself. This choice affects precision, waste reduction, and overall production speed. In simpler terms, the right tool holder can make or break your manufacturing process. So, understanding the importance of CNC efficiency is step one. It's what keeps production costs down while maintaining top-notch quality and meeting production deadlines. Let's dive deeper into how selecting the best tool holder can transform your CNC operations.

Understanding the Role of Tool Holders in CNC Machines

In the world of CNC machining, the tool holder might not get the spotlight, but it's a real game changer. Think of it as the bridge. On one side, you've got your cutting tool, and on the other, the mighty CNC machine itself. The tool holder's job? To make sure these two can work together perfectly. Get this right, and you've just taken a big step towards top-notch precision and efficiency on the shop floor. At its core, a tool holder affects the performance by ensuring the cutting tool is securely positioned. This means less vibration and more accuracy—a win-win in the machining world. Whether you're drilling, milling, or turning, picking the right tool holder impacts everything from the quality of your work to the life span of both the tools and the machine. So, while it might seem like a small part of the puzzle, skipping on understanding tool holders is like trying to run before you can walk. Bottom line: start paying attention to your tool holders. It's a small thing that can make a big difference.

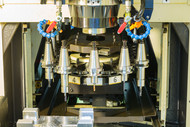

Types of Tool Holders and Their Uses

When it comes to CNC machining, picking the right tool holder is crucial. Think of it as matching the perfect pair of shoes to your outfit; the right choice can significantly boost performance. Let me break it down for you. First up, we've got the collet chuck holder. It's like the trusty sneakers of the CNC world—versatile and reliable. You'll use it for precision work, holding onto bits and end mills like a pro. Next, there's the hydraulic tool holder. Imagine a pair of high-tech running shoes. It absorbs vibrations, making it perfect for high-speed machining with less noise and a smoother finish. Then we have the shrink fit holder. It's the snug, custom-fitted boot for your bits, offering stellar precision and grip thanks to a tight thermal fit—ideal for high-speed and heavy-duty machining. And don't forget the side-lock holder. It's the work boots of the group, simple but solid, mainly used for hefty drilling tasks. Each type impacts your CNC machine's performance, precision, and finish quality. So, matching the task at hand with the proper tool holder isn't just smart—it's essential. You wouldn't wear flip-flops to run a marathon, right? Same goes for CNC machining; pick the right tool holder for the job.

Key Factors to Consider When Selecting Tool Holders

Choosing the right tool holder is critical for maximizing CNC machine efficiency. The big hitters? Compatibility, balance, and material. First up, compatibility. Ensure the holder fits your machine and tool. A mismatch can halt your operation. Next, let’s talk about balance. For high-speed operations, balance is king. It minimizes vibrations, meaning better precision and longer tool life. Lastly, material matters. Look for toughness and thermal resistance. High-speed steel is common, but carbide or ceramic might fit specific jobs better. Remember, the right choice boosts performance and reduces downtime. Keep these factors front and center, and you’re set for success.

Balancing Precision and Durability in Tool Holder Choice

Choosing the right tool holder is all about finding the perfect balance between precision and durability. A tool holder that lacks precision can lead to inaccuracies in your work, throwing off dimensions and ruining parts. On the flip side, a tool holder that's not built to last can break down in the middle of a job, causing delays and extra costs. It's like picking a player for your team — you want someone reliable who can also deliver top-notch performance. There's a range of tool holders out there, from the sturdy CAT and BT holders, which are great for heavy-duty jobs, to the high-precision HSK holders that excel in high-speed CNC machining. Each type has its own highlights. For instance, HSK holders clamp down harder as spindle speed increases, ensuring accuracy at high speeds. It's like they're built for sprinting without losing their grip. When choosing, consider what's more critical for your projects. Heavy-duty work that needs brute force? Go for CAT or BT. Or is it high-speed, detail-oriented tasks? Then HSK might be your MVP. Remember, the goal is to get that perfect match that won't let you down mid-game.

Enhancing Productivity Through the Right Tool Holder Selection

Choosing the right tool holder for your CNC machine is like picking the best running shoes for a marathon: it makes all the difference in performance and outcome. The right tool holder boosts your CNC machine's precision, speed, and longevity, directly impacting productivity. Let's break it down. Firstly, understand that tool holders come in various types, such as hydraulic, shrink-fit, and mechanical (like collet chucks). Each has its pros and cons. For example, hydraulic holders offer great precision and balance, perfect for high-speed operations. Shrink-fit holders, known for their excellent grip and minimal runout, suit applications requiring high accuracy. Meanwhile, collet chucks, versatile and cost-effective, work well for a wide range of tasks. The key is to match the tool holder to your specific machining needs. Consider the material you're working with, the type of operation (like heavy milling or fine drilling), and your machine's capabilities. A well-chosen tool holder reduces vibration, extends tool life, and enhances the surface finish of your product, leading to less waste and more efficient production. So, don't underestimate the impact of the right tool holder. It might seem like a small part of your setup, but it's a powerhouse in maximizing CNC efficiency.

Case Studies: Successful Implementations of Optimal Tool Holders

Companies have been searching for ways to boost their CNC efficiency and productivity. One straightforward strategy that has proven effective involves choosing the right tool holders. Let's look at a couple of success stories. First up, we have Advanced Machining Solutions, a company that faced frequent downtimes due to tool misalignment and breakage. They shifted to hydraulic and shrink-fit tool holders, known for their superior precision and vibration damping. The result? A staggering 30% increase in machine uptime and a significant reduction in tool replacement costs. Next, is TechFab Inc., which struggled with long setup times. By adopting quick-change tool holders, they not only slashed setup time by 50% but also noticed a remarkable improvement in product consistency. These case studies underline a clear message: the right tool holder selection can drastically improve your CNC operations. It's not just about the initial cost; it's about the long-term efficiency and savings.

Maintenance Tips for Your Tool Holders

Keeping your tool holders in top shape is crucial for the long haul. Simple, routine checks can prevent major headaches down the line. First off, clean them regularly. Dust and debris are the enemies here; they can lead to wear and tear that affects your CNC machine's precision. Use a soft cloth and, if necessary, mild cleaning agents. No harsh chemicals that can damage the tool holder's surface. Secondly, inspect for signs of damage or wear often. Cracks or corrosion? That's a red flag. Early detection means you can replace or repair before it causes bigger issues. Also, ensure the tool holder's compatibility with your spindle. A mismatch can lead to poor performance and even damage your machine. Lastly, lubricate as recommended by the manufacturer. Proper lubrication reduces friction and keeps operations smooth. Remember, investing a little time in maintenance can save you a lot in the long run.

Common Mistakes to Avoid in Tool Holder Selection

Choosing the wrong tool holder can lead to a world of trouble, seriously messing up your CNC machine's efficiency. Let's put it straight - picking the right tool holder is not rocket science, but a few common missteps can trip you up big time. First off, ignoring the compatibility between your machine spindle and the tool holder is a rookie mistake. It's like trying to fit a square peg in a round hole – it just won't work. Secondly, overlooking the tool holder's balance quality is asking for trouble. A poorly balanced holder can ruin your machine's performance, leading to less than ideal results on your workpiece, and nobody wants that. Also, skimping on quality to save a few bucks? Bad idea. A cheaper tool holder might look good on your budget now, but when it wears out quickly or worse, damages your machine, those savings evaporate. Last but not least, not considering the application is a blunder. Different jobs need different tool holders. Using a one-size-fits-all approach will hamper your machine's capability to do its best work. So, keep these points in mind and choose wisely. Your CNC machine will thank you.

Conclusion: The Impact of the Right Tool Holder on CNC Efficiency

Choosing the right tool holder can transform your CNC operations from good to exceptional. It's the difference between consistent, high-quality production and facing regular setbacks due to tool misalignment or breakage. The impact stretches beyond just the machinery's performance; it influences the lifespan of your tools, the finish of your products, and ultimately, your bottom line. By opting for a tool holder that matches your machine's specifications and the demands of the job, you set up your CNC operations for smoother runs and fewer headaches. Remember, investing in the right tool holder is not merely a purchase; it's an investment in efficiency, quality, and reliability. Consider this choice carefully, as it holds the power to elevate your CNC game significantly.