MANUAL TOGGLE CLAMPS

-

Product NameQtyPriceSubtotal

-

R.M.T. - Ridiculous Machine Tools

7500LB U-HOOK FLG BASE LATCH CLAMP WITHOUT LATCH PLATE Machinist Choice

Qty :Price :$83.86$45.02Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

2000LB U-HOOK FLG BASE LATCH CLAMP Machinist Choice

Qty :Price :$42.72$17.58Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

2000LB Horizontal Flanged Base, Self-Locking Latch Clamp LATCH INCLUDED Machinist Choice™

Qty :Price :$71.68$36.31Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

500LB U-BAR FLG BASE VERTICAL HOLD-DOWN CLAMP STAINLESS STEEL Machinist Choice

Qty :Price :$57.13$27.18Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

300LB 5/16-18 THRD BDY STRAIGHT LINE CLAMP Machinist Choice

Qty :Price :$35.16$15.46Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

400LB 5/16-18 FLG BASE STRAIGHT LINE CLAMP Machinist Choice

Qty :Price :$38.72$15.21Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

1000LB U-BAR FLG BASE VERTICAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$55.73$26.27Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

700LB U-HOOK FLG BASE LATCH CLAMP Machinist Choice

Qty :Price :$28.93$10.97Subtotal : $0.00

History of Manual Toggle Clamps: Everything You Need to Know about Toggle Clamps

The history of manual toggle clamps is a topic that spans over a century, reflecting advancements in manufacturing processes, mechanical engineering, and the diversification of industrial and commercial applications. Although detailed historical records on the very first invention of toggle clamps might be sparse, we can trace their evolution and categorize them into several types based on their mechanism and applications. Ridiculous Machine Tools did not invent Manual Toggle Clamps but we have mastered the art of manufacturing them so we can provide them to you at the most affordable price in the industry. Here we will provide you with a comprehensive overview of everything you need to know about Toggle Clamps uses and mechanism. For the most granular mechanical and engineering specifications, direct consultation with one of our engineers would always be the best place to start.

Show MoreHow do you effectively use a Manual Toggle Clamp?

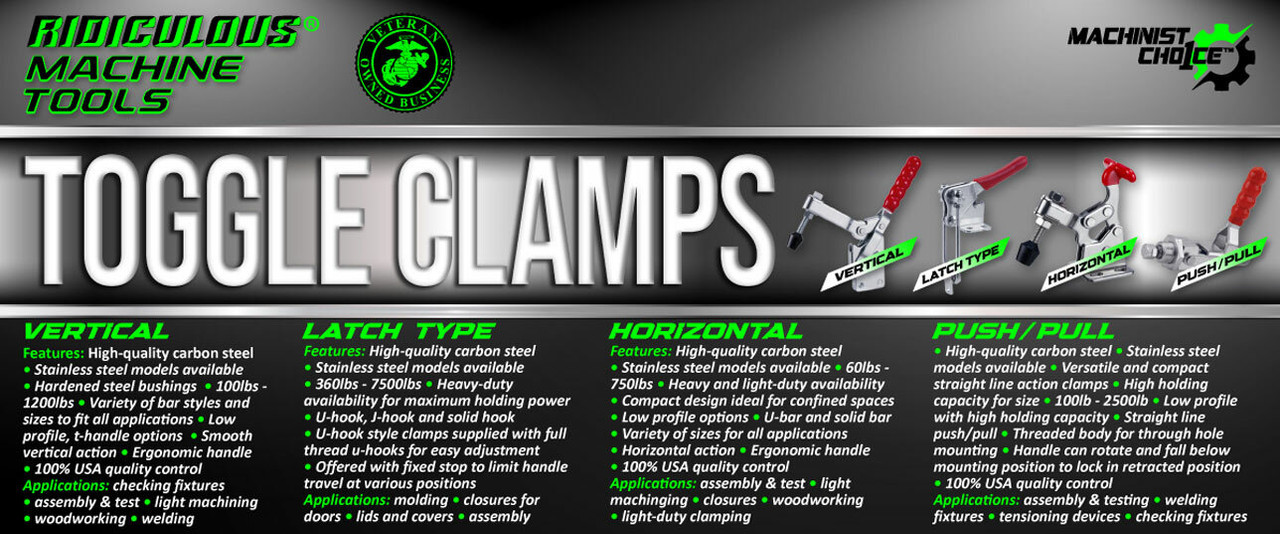

Vertical Hold Down Toggle Clamps

Vertical toggle clamps are exceptionally suited for situations where vertical space above the workpiece is limited, and maintaining a streamlined profile is crucial. This design ensures the clamp extends upwards and occupies minimal space horizontally, making it an ideal choice when you're working within a confined area. With the handle positioned vertically when the clamp is locked, this configuration allows for efficient use of space above the workpiece. This characteristic is particularly beneficial, enabling the operator to maximize the working area's potential without the clamp interfering.

Show MoreHorizontal Hold Down Toggle Clamps

Horizontal toggle clamps are exceptionally suited for situations where vertical space above the workpiece is limited, and maintaining a streamlined profile is crucial. This design ensures the clamp extends upwards and occupies minimal space horizontally, making it an ideal choice when you're working within a confined area. With the handle positioned Horizontally when the clamp is locked, this configuration allows for efficient use of space above the workpiece. This characteristic is particularly beneficial, enabling the operator to maximize the working area's potential without the clamp interfering. The vertical orientation of the handle when engaged means the clamp's footprint is minimized in the vertical direction, which is a significant advantage.

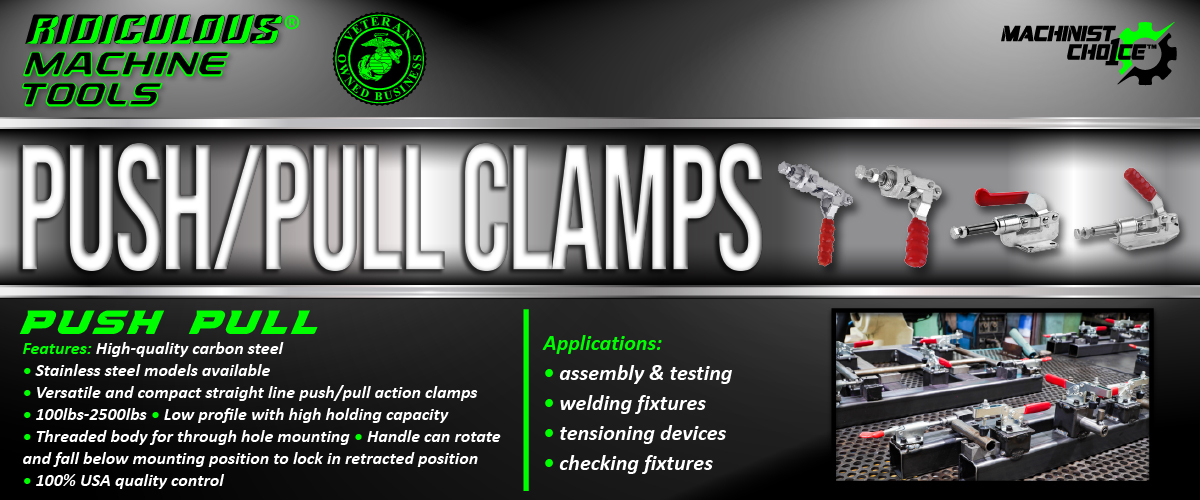

Show MorePush-Pull Over Center Toggle Clamps

The general use of a push-pull toggle clamp involves securing or holding workpieces in a fixed position for various operations such as welding, machining, assembly, and inspection. The user engages the clamp by operating a handle that activates a straight-line, push-pull action, exerting a clamping force directly onto the workpiece in any direction needed. This action can either push components together or pull them against a supporting fixture, depending on the setup. Once the desired position is achieved, the toggle mechanism locks the over center clamp in place, ensuring the workpiece remains stationary without continuous manual pressure.

Show MoreStraight-Line Action Industrial Clamps

The straight-line toggle clamp's design is often more straightforward, focusing on the efficient transmission of force in a singular direction. This simplicity can translate to higher clamping efficiency and reliability in applications that demand precise force application without the need for adjustment in the direction of force. Straight-line industrial toggle clamps excel in situations where a uniform, direct force is essential for holding parts without any shift or tilt. This is particularly important in machining applications, assembly, or when working with delicate components that could be damaged by uneven pressure or shifting.

Show MoreLatch Toggle Clamps

The toggle mechanism within the clamp is what allows it to apply a significant amount of clamping force with minimal effort from the user. Once the clamp is in the locked position, the toggle mechanism ensures a secure hold, preventing accidental release. The clamp remains locked until the handle is manually disengaged, releasing the tension and allowing the clamped pieces to be separated.

Show MoreHook Latch Clamps

The core design elements of a hook style latch clamp include a handle, a base, a movable hook, and a latch plate or eye. The operational mechanism is straightforward yet effective: as the handle is activated, it drives the hook to catch onto a latch plate or eyelet attached to the opposing component. This mechanism draws the two parts together, securing them in place. The toggle action ensures that once the hook is engaged and the clamp locked, a strong and reliable hold is maintained, preventing accidental disengagement until the handle is manually released.

Show MoreCommon Principles Across Types

The specificity of each design caters to the unique requirements of various applications, from heavy-duty machining to delicate assembly work, demonstrating the toggle clamp's versatility and efficiency as a tool in manufacturing and engineering contexts.

Show MoreFrequently Asked Questions

-

1. What type of steel are your clamp made from?

All of our standard clamps are made from high quality Carbon Steel or 304 Stainless Steel depending on your application. Please contact us at techsupport@ridiculousmachinetools.com if you need help confirming the right clamp for your application.

-

2. Can you make Special adjustable Clamps?

Yes, We can make any clamp that you need for your applicaton. If we currently do not offer the clamp please contact us at orders@ridiculousmachinetools.com and request a quote. If you have the competitors part number that is always easiest to provide to us so we can cross and quote. There may be a 500 pice minimum for special clamp.

-

3. How do I choose the correct Manual Toggle Clamps for my Fixture set up in my CNC Machine?

To ensure a smooth machining operation, it is crucial to have a comprehensive understanding of the workpiece you are about to machine. Consider all the necessary operations and consider the positioning of the toggle clamps' handle. This step will prevent any interference with the machining process. When configuring and designing your fixture, determine whether a Horizontal Handle, Vertical Handle, or a push-pull handle is required to ensure proper clearance and safety. At RMT, we are always ready to assist you in designing your fixture. Feel free to contact us for any help you may need.

-

4. How are the prices for the RMT Toggle Clamps so reasonable?

At RMT we offer our complete offering of high-quality toggle clamps DIRECT to the machine shop, Woodworker, Welder or facility in need of our clamps. We do not sell through distribution, which enables us to offer our quality clamps at the most competitive price in the industry. Try us out and you will see why we are called the machinist choice...

-

5. What are the mechanical aspects or a manucal toggle clamp?

The toggle mechanism at the heart of manual toggle clamps is an elegant yet simple mechanical principle that leverages a series of levers and pivots to achieve a strong and secure hold with minimal effort. The basic principle involves converting a small manual force applied to the handle into a larger clamping force through the geometric arrangement of the mechanism's components. This principle is based on the concept of mechanical advantage, which is the ratio of output force to input force in a system. The "toggle" part of the process occurs when the mechanism goes over-center, locking it into place with a positive locking action that resists unintentional opening under load.

-

6. How do material properties affect the performance of small hold down toggle clamps?

Material properties, such as strength, durability, and corrosion resistance, directly impact the performance and longevity of toggle clamps. At RMT we manufacture our standard clamps out of High Grade Carbon Steel and 304 Stainless Steel at the moment. These materials are used depending on application to ensure the clamp can withstand the mechanical stresses and environmental conditions it will be exposed to. If you are unsure on which material would be best for your application please contact us and we will asist you in finding the right clamps for the job.

-

7. What is a vertical Toggle Clamp?

A vertical toggle clamp is identified by the orientation of its handle when the clamp is in its fully engaged, locked, or closed state. Unlike its horizontal counterpart, the handle of a vertical toggle clamp stands upright in a vertical plane perpendicular to the base or the surface it's mounted on when the clamp is locked. This vertical orientation during engagement means that to operate the clamp, you will typically pull the handle upwards or push it downwards, moving it through a vertical arc. Once the clamp is fully engaged and the mechanism is locked, the handle will be positioned upwards, pointing away from the workpiece. This characteristic is especially advantageous in workspaces where horizontal space around the workpiece is constrained, as it allows the handle to occupy minimal space laterally.

-

8. What is a Horizontal Toggle Clamps

A horizontal toggle clamp is distinguished not just by the motion of its handle but significantly by its position when the clamp is fully engaged, locked, or in the closed position. When you activate a horizontal toggle clamp by moving its handle, the handle lies in a horizontal plane parallel to the base or the mounting surface at the point of full engagement. This horizontal orientation of the handle, when the clamp is locked, is what fundamentally classifies it as a "horizontal" toggle clamp. This means that as you apply force to close the clamp, you'll move the handle sideways, parallel to the workbench or surface on which the clamp is mounted. Once the handle reaches its locked position, it will be lying flat, in line with the horizon, hence the term "horizontal." This design is particularly useful in scenarios where vertical space is limited, allowing for the clamp to remain out of the way, maintaining a low profile above the workpiece.

-

9. What is a Push Pull Toggle Clamp?

The push-pull toggle clamp is a mechanical device engineered to perform clamping operations by applying a linear motion, either pushing or pulling, to secure or release workpieces. Unlike Straight-Line Toggle clamps that focus on an efficient transmission of force in a singular direction Push-Pull Clamps can be locked in both directions making them more versatile that Straight Line Toggle Clamps. This unique mechanism allows for direct application of force in either direction making them exceptionally versatile in various applications.

-

10. What is a Straight Line Toggle Clamp?

Straight-line toggle clamps excel in situations where a uniform, direct force is essential for holding parts without any shift or tilt. This is particularly important in machining operations, assembly, or when working with delicate components that could be damaged by uneven pressure or shifting. On the other hand, push-pull toggle clamps offer the flexibility of adjusting the direction of the applied force, either pushing away or pulling towards, which can be advantageous in assembly operations, fixture setups, or when repositioning is needed during the clamping process.

-

11. What is a Latch Toggle Clamp?

A latch toggle clamp is a specialized type of clamping device designed to securely fasten or hold two separate pieces together using a latching mechanism. The clamp typically consists of a handle, a base, a clamping arm, U-bolt or hook, and a latch plate. The handle operates the clamping mechanism, which moves the clamping arm into position. When the handle is engaged, the arm moves to latch onto a corresponding plate or catch mounted on the opposite piece to be clamped. This action effectively pulls and secures the two pieces together. This type of clamp is particularly useful in applications where parts need to be quickly and securely locked in place and then released with equal speed and efficiency. Latch toggle clamps are widely used across various industries, including manufacturing, woodworking, automotive, and metalworking, woodworking toggle clamps due to their versatility and robustness.

-

12. What is a Hook Latch Clamp?

A hook style latch clamp is a specific variant of toggle clamps designed to fasten or hold two components securely together by engaging a hook mechanism. This type of clamp is particularly valued in scenarios where direct pulling action is required to join or align parts with precision and strength. Hook style latch clamps are utilized across a diverse range of fields, including automotive repair, construction, manufacturing, and woodworking, showcasing their adaptability and effectiveness.