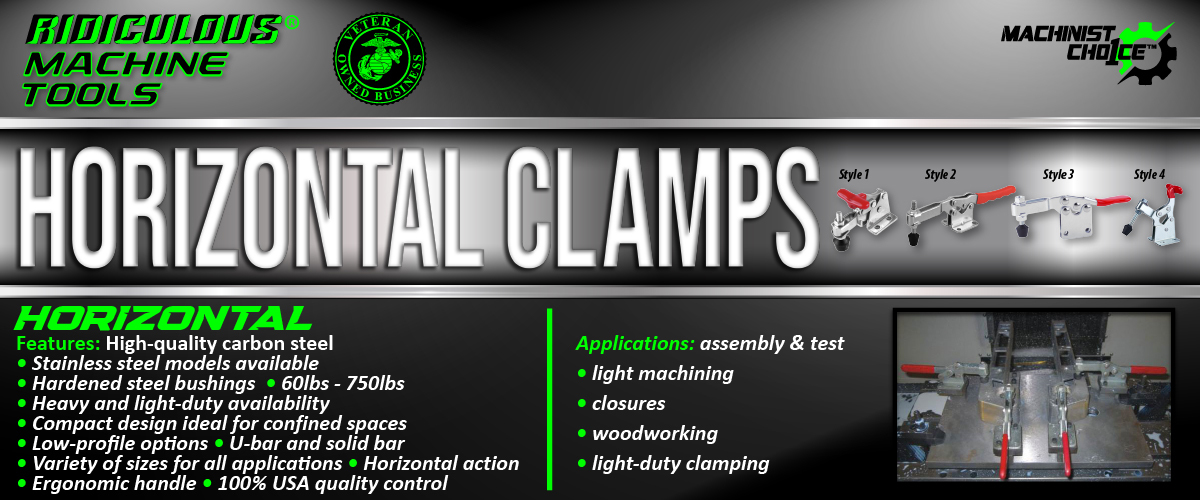

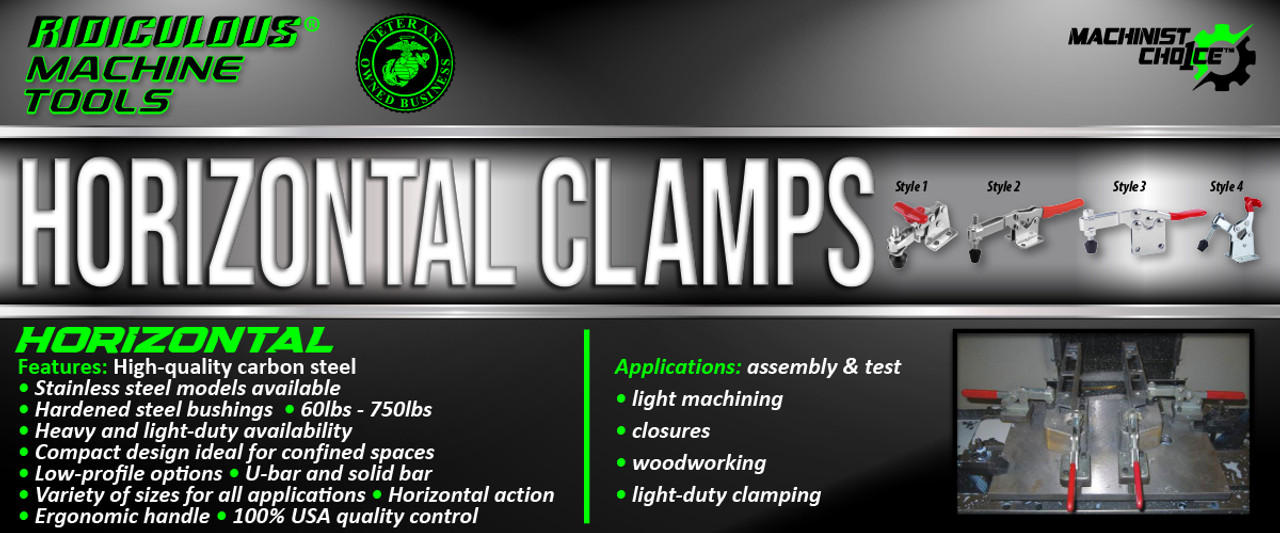

HORIZONTAL Manual Toggle Clamps

-

Product NameQtyPriceSubtotal

-

R.M.T. - Ridiculous Machine Tools

150LB U-BAR FLG BASE HORIZONTAL HOLD-DOWN CLAMP STAINLESS STEEL Machinist Choice

Qty :Price :$33.55$17.53Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

200LB U-BAR FLG BASE HORIZONTAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$24.09$9.23Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

60LB U-BAR FLG BASE HORIZONTAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$19.91$7.51Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

750LB U-BAR FLG BASE HORIZONTAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$41.29$17.52Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

300LB U-BAR FLG BASE HORIZONTAL HOLD-DOWN CLAMP STAINLESS STEEL Machinist Choice

Qty :Price :$63.69$37.00Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

150LB FLNG BASE U-BAR LOW PROFILE HORIZONTAL TOGGLE CLAMP Machinist Choice

Qty :Price :$26.18$10.74Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

200LB U-BAR STGHT BASE HORIZONTAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$24.10$9.23Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

200LB SOLID BAR FLGD BASE HORIZONTAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$24.09$9.23Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

500LB U-BAR STGHT BASE HORIZONTAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$28.42$11.13Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

500LB U-BAR FLG BASE HORIZONTAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$28.27$11.03Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

60LB Solid Bar STRAIGHT BASE HORIZONTAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$19.91$7.51Subtotal : $0.00 -

R.M.T. - Ridiculous Machine Tools

300LB U-BAR FLG BASE HORIZONTAL HOLD-DOWN CLAMP Machinist Choice

Qty :Price :$30.62$12.73Subtotal : $0.00

Description: A horizontal toggle clamp is distinguished not just by the motion of its handle but significantly by its position when the clamp is fully engaged, locked, or in the closed position. When you activate a horizontal toggle clamp by moving its handle, the handle lies in a horizontal plane parallel to the base or the mounting surface at the point of full engagement. This horizontal orientation of the handle, when the clamp is locked, is what fundamentally classifies it as a "horizontal" toggle clamp. This means that as you apply force to close the clamp, you'll move the handle sideways, parallel to the workbench or surface on which the clamp is mounted. Once the handle reaches its locked position, it will be lying flat, in line with the horizon, hence the term "horizontal." This design is particularly useful in scenarios where vertical space is limited, allowing for the clamp to remain out of the way, maintaining a low profile above the workpiece.

Show MoreHorizontal Toggle Clamps in the CNC Machining Process

At Ridiculous Machine Tools, we understand the crucial role that horizontal manual toggle clamps play in the CNC machining process. These clamps are designed to provide substantial clamping force with minimal effort, ensuring precision and stability for workpieces during machining. Their unique handle orientation offers additional clearance, enhancing operational ease around the workpiece. Versatile across a variety of sizes and configurations, these clamps are suited for any project, from delicate components to large, robust pieces.

Show MoreWoodworking with Horizontal Toggle Clamps

In the realm of woodworking, horizontal toggle clamps stand out as a game-changer, bringing unparalleled efficiency and precision to craftsmen and hobbyists alike. These clamps not only secure your workpieces firmly during various stages of woodworking but also enhance the safety and quality of your creations with their robust clamping force applied through a simple toggle mechanism. This feature is a boon for woodworkers, significantly reducing the effort required to maintain a strong grip on materials during essential tasks like cutting, sanding, or drilling.

Show MoreWelding and Fabrication with Horizontal Toggle Clamps

Horizontal toggle clamps are a cornerstone in the world of welding and fabrication, bringing unmatched levels of efficiency, precision, and safety to the forefront of metalworking. These robust tools are engineered to offer a steadfast grip on workpieces, dramatically enhancing stability, accuracy, and the quality of the finished project during intricate welding and fabrication tasks.

Show MoreFrequently Asked Questions

-

1. What is the difference between Horizontal and Vertical Toggle Clamps?

The key distinction between Horizontal and Vertical toggle clamps lies in the orientation of their handles during the clamp's engagement or locking phase. With vertical toggle clamps, the handle stands upright, perpendicular to the mounting surface, when the clamp is fully engaged or in its locked position. Conversely, horizontal toggle clamps feature a handle that aligns parallel to the mounting surface, lying flat when the clamp is securely locked.

This fundamental difference in design directly influences the clamp's application based on the spatial constraints and requirements of your project. For setups where vertical space is limited, horizontal toggle clamps offer a low-profile solution, keeping work areas clear and accessible. Alternatively, in scenarios where lateral space around the workpiece is constrained, vertical toggle clamps provide an effective clamping solution without extending into the workspace.

Choosing between vertical and horizontal toggle clamps depends on the specific needs of your workpiece and the configuration of your machinery or fixture. As a manufacturing engineer, I recommend assessing both your spatial limitations and the demands of your project to select the most appropriate toggle clamp orientation, ensuring optimal performance and efficiency in your clamping operations.

-

2. What are the benefits of using horizontal toggle clamps in machining processes?

Horizontal toggle clamps provide a secure and stable grip on workpieces, allowing for precise and accurate machining operations. They are essential for holding materials in place, preventing movement or slippage during drilling, milling, or cutting processes.

-

3.How do I choose the right horizontal toggle clamp for my application?

When selecting a horizontal toggle clamp, consider factors such as the clamping force required, the size and shape of the workpiece, and the space available for mounting. It's essential to match the clamp's capacity and reach the specific requirements of your machining project.

-

4. What features should I look for in a high-quality horizontal toggle clamp?

Look for horizontal toggle clamps with sturdy construction, durable materials, and ergonomic handle designs for ease of use. Features such as adjustable clamping pressure, quick-release mechanisms, and anti-slip grips can enhance the functionality and performance of the clamp.

-

5. How can I ensure proper maintenance and care for my horizontal toggle clamps?

To maintain the effectiveness of your horizontal toggle clamps, regularly inspect them for signs of wear, damage, or misalignment. Keep the clamping surfaces clean and free from debris and lubricate moving parts as recommended by the manufacturer to ensure smooth operation.

-

6.Can horizontal toggle clamps be customized to meet specific machining needs?

Yes, Ridiculous Machine Tools offer customization options for horizontal toggle clamps, including variations in handle styles, clamping capacities, and mounting configurations. Customized solutions can be tailored to accommodate unique workpiece shapes, sizes, and material requirements for specialized machining applications.

-

7.What are Horizontal Toggle Clamps?

A horizontal toggle clamp is distinguished not just by the motion of its handle but significantly by its position when the clamp is fully engaged, locked, or in the closed position. When you activate a horizontal toggle clamp by moving its handle, the handle lies in a horizontal plane parallel to the base or the mounting surface at the point of full engagement. This horizontal orientation of the handle, when the clamp is locked, is what fundamentally classifies it as a "horizontal" toggle clamp. This means that as you apply force to close the clamp, you'll move the handle sideways, parallel to the workbench or surface on which the clamp is mounted. Once the handle reaches its locked position, it will be lying flat, in line with the horizon, hence the term "horizontal." This design is particularly useful in scenarios where vertical space is limited, allowing for the clamp to remain out of the way, maintaining a low profile above the workpiece.