The Evolution of Workholding Clamps: From Basics to Advanced Engineering

Posted by RMT on Mar 15th 2024

Introduction to Workholding Clamps

Workholding clamps may not spring to mind at first when thinking about industrial innovation, yet their evolution is a vital component of the manufacturing process. Essentially, these tools secure your workpiece in place while machines and tools perform their tasks. Initially simple clamps used by craftsmen shaping materials, they have progressed into sophisticated devices designed for precision and efficiency. In the early days, workholding relied on sheer force, using whatever was available to secure materials. As we transitioned to computer-controlled manufacturing, clamps have also evolved to meet modern technological demands. Today, these clamps are as essential as the cutting-edge machines they complement, ensuring the success of your project from inception to completion.

The Early Days: Basic Workholding Solutions

In the early days, workholding was rudimentary yet effective. Craftsmen utilized whatever materials were available, such as wooden blocks and wedges, to secure their workpieces. Precision was not a top priority at the time, with much of the work relying on manual labor. Picture a blacksmith diligently hammering away at metal on an anvil—an uncomplicated method that got the job done. However, the simplicity of these techniques had its limitations, particularly as industries progressed and demanded greater precision and efficiency. This necessity drove the innovation of mechanical clamps that provided more stability than traditional wedges. Even in these early mechanical designs, the foundation of today's advanced workholding solutions was evident—prioritizing functionality with a firm grasp to prevent any movement during the work process. These initial devices laid the groundwork for the innovative clamping technologies we now witness in modern times.

The Role of Workholding Toggle Clamps in Manufacturing

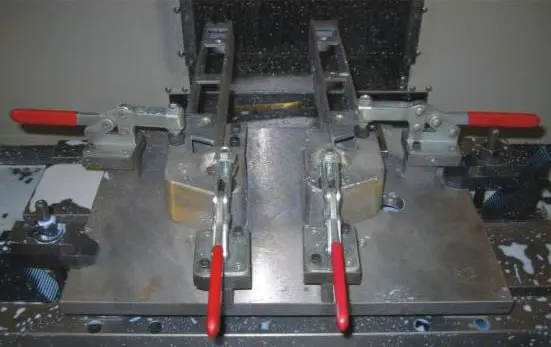

Workholding clamps are the unsung heroes in manufacturing. They're essential for keeping workpieces secure during machining or assembly. Manual Toggle Clamps have become one of the most widely used clamping systems in the world. Without them, you couldn't drill, mill, or cut with precision. Their role is simple: they hold your material firmly in place so your tools can work their magic. But don't be fooled by their simplicity—these clamps are critical for achieving the accuracy needed in today's advanced manufacturing processes. They come in various shapes and sizes, each designed for specific tasks—be it holding a delicate piece of electronics or a heavy steel beam. From manual screw clamps to advanced hydraulic systems, the evolution of workholding clamps directly affects how efficiently a factory operates, and in turn, how well any final product turns out.

Material Advancements in Clamp Design

In the realm of clamps, it's not just about shape and size, the material magic unfolds real strength and durability. Gone are the days of the simple iron grip; now we're talking alloys that can take a hit and not flinch. Stainless steel's the Herculean choice for environments that like to pit and corrode – it stands its ground. Aluminum's got the spotlight for being light as a feather but tough enough to lock things down without bulking up the load. And don't forget composites – they're the newcomers strutting a balance of brawn and weight, and they're playing the rust card pretty darn well, too. With materials getting a high-tech boost, clamps are not just holding on, they're getting stronger, lasting longer, and suiting up for any challenge the job throws their way.

Precision Engineering: The Shift to Advanced Workholding

Precision matters. It's what takes workholding clamps from good to great. As we keep innovating, workholding has seen a leap. We've moved from basic clamps to sophisticated devices. Clamps aren't just about holding stuff anymore; they're about precision. Think about it like your game controller. You want the one that gives you perfect control, right? Same with clamps. Advanced engineering lets manufacturers achieve flawless holding pressures, exact placements, and consistent results. It isn't just a clamp; it's a finely-tuned instrument. This shift means complex jobs are handled better and with ease, making efficiency the name of the game.

The Impact of Technology on Workholding Clamps

Technology has reshaped workholding clamps, making them more precise, stronger, and easier to use. In the past, clamps were mostly manual, requiring a lot of effort to ensure a secure hold. But now, with advancements in engineering and materials science, we've got clamps that you can almost set and forget. They clamp down with consistent pressure, and many have micro-adjustments for that perfect grip. Computer Numerical Control (CNC) machines have also elevated workholding clamps. Imagine high-tech clamps programmed to hold parts at the exact tension needed for machining. That's precision that manual methods struggle to match. These tech upgrades not only save time but reduce the margin of error, making jobs quicker and results more reliable. So, whether you're in an industrial setting or a home workshop, technology's touch on clamps means better work, with less sweat and more control.

Hydraulic and Pneumatic Clamps: A Game Changer

Hydraulic and pneumatic clamps have revolutionized how we approach workholding. These dynamic tools use fluid and air pressure, respectively, to deliver clamping force. This means instead of manually tightening a clamp, a simple button press does the job. It's efficiency at its finest. Hydraulic clamps bring serious clamping pressure, ideal for large-scale or heavy-duty tasks. Pneumatic clamps, on the other hand, are your quicker, more lightweight champions, perfect for high-speed operations and repetitive tasks. What's more, both types offer precision that manual clamps struggle to match. They come at a higher upfront cost, sure, but they pay off with improved productivity and reduced labor. It's not just about holding something in place; it's doing it smarter and faster.

The Rise of Modular Workholding Systems

Modular workholding systems have transformed the way we secure parts during manufacturing. Why? Because they're ridiculously versatile. Unlike traditional clamps, which are, well, a bit of a one-trick pony, modular systems let you mix and match components to fit the task at hand. Imagine playing with building blocks – that’s the level of flexibility we're talking about. You can tailor your setup for any job, big or small, without sweating it. This adaptability means you're swift in setting up for complex projects and just as quick to shift gears for smaller tasks. The result? Less time tweaking your setup and more time actually making things. Plus, since modular clamps are so precise, they boost your efficiency and the quality of your work without breaking a sweat. Better efficiency, better quality, and they don’t demand a whole different clamp for every new piece – that's the kind of smart thinking that’s shot modular workholding systems right to the top.

Workholding Clamps in the Era of Automation

The role of workholding clamps has become critical in today's automated manufacturing environments. These clamps are no simple devices; they've evolved to interact seamlessly with robotic systems and CNC machines, offering precision and reliability. In an automated shop floor, clamps must quickly and securely hold workpieces, often with minimal human intervention. This shift benefits production, as manual setting and adjustments become less frequent, reducing downtime and increasing productivity. The sheer variety of clamps – from hydraulic and pneumatic to toggle and swing clamps – meets the need for versatility in handling different materials and shapes. Advanced engineering has indeed fine-tuned these tools to meet the demands of modern manufacturing, ensuring that workholding clamps remain indispensable allies in the quest for efficiency and consistency.

The Future Outlook: What's Next for Workholding Clamps?

The game isn't over yet for workholding clamps; there's a lot in store for the future. Innovators are exploring ways to enhance these tools significantly. Imagine smarter clamps with sensors that provide precise pressure readings—no more guesswork. The advancements go beyond just stronger materials and designs. Envision clamps that adjust seamlessly, altering their shape and size to secure different parts effortlessly. The aim is to save time and boost efficiency. Anticipate a tech upgrade for workholding clamps, positioning them as integral components in automated systems, collaborating closely with robots. The future entails minimal manual adjustments, enhanced precision, and reduced human errors. Brace yourself for the evolution of workholding clamps into highly sophisticated and practical tools.