5 Tips for Selecting the Best Lathe Centers for Your Workshop

Posted by RMT on Mar 20th 2024

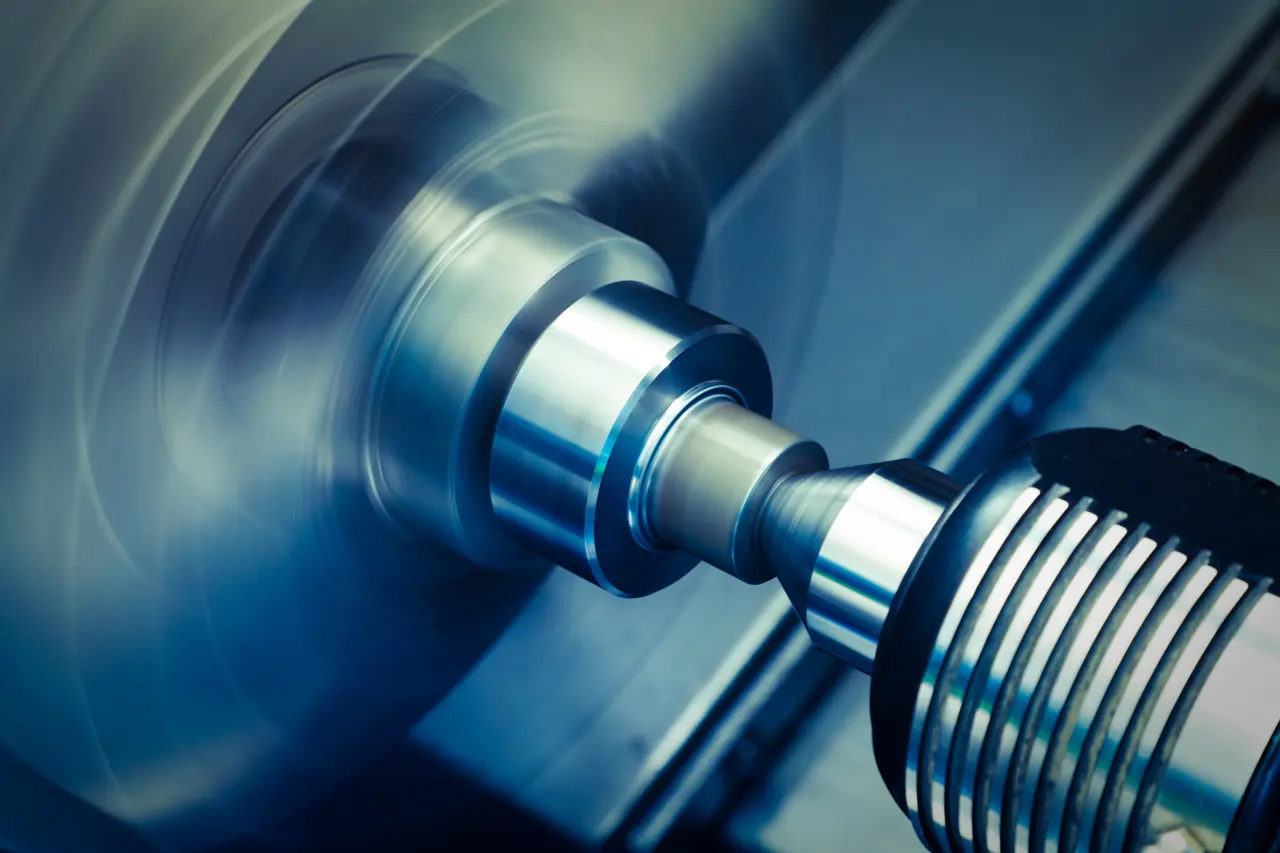

Understanding Lathe Centers: An Introduction

Lathe centers are crucial for any metalworking or woodworking shop. Think of them as the support system that holds your workpiece in place while it spins. Without a sturdy lathe center, achieving precision in your projects is almost impossible. There are two main types: live centers and dead centers. Live centers rotate with the workpiece, reducing friction and wear. They're fantastic for long or heavy pieces. Dead centers, on the other hand, stay still. They’re simple but require lubrication to stop the workpiece from burning due to friction. Choosing the right type depends on your project needs. Remember, a solid lathe center means better work, less waste, and more satisfaction with your final product.

The Different Types of Lathe Centers

When we dive into lathe centers, it's essential to know there are mainly two types: live centers and dead centers. Live centers rotate with the workpiece, providing more flexibility and less friction, ideal for precision work. On the flip side, Dead centers stay still, lodged firmly in the tailstock, offering a stable support point for your workpiece. Within these two categories, there's more variety based on specific needs. For instance, within live centers, you'll find ones designed for heavy-duty tasks, known for their durability and ability to handle larger, heavier workpieces. Then, there are high-precision centers, crafted for jobs that demand extreme accuracy. Dead centers also come in different materials like steel, carbide-tipped, or even coated with special materials to reduce friction and wear. Each type has its unique advantages, depending on the materials you're working with and the precision required. So, selecting the right one is crucial for achieving the desired results in your projects.

Key Features to Look for in High-Quality Lathe Centers

When scouting for the best lathe centers for your workshop, pay attention to a few critical features. First, consider the material. High-quality lathe centers are typically made from hardened steel or carbide. These materials can handle the heat and pressure without wearing down quickly. Next, look at the tip type. A dead center has a fixed tip, ideal for precise work, while a live center rotates with the workpiece, offering flexibility. Precision matters too. Choose a lathe center with tight tolerances to ensure accuracy in your projects. Additionally, the center's load capacity should match your typical workpiece weight. Lastly, think about compatibility. Ensure the lathe center fits your machine type and size. By focusing on these features, you'll equip your workshop with a lathe center that meets your needs and enhances your work quality.

Determining the Right Size and Type of Lathe Center for Your Needs

Getting the right size and type of lathe center is crucial for your workshop tasks. It's not as complicated as it might seem. First, look at the size of workpieces you usually handle. Are they big, medium, or small? This tells you the size of the lathe center you need. Bigger pieces need a bigger lathe center. Simple as that. Next, think about the type of work you do. If precision is your game, a live center, which spins with the workpiece, might be your best bet. For rougher, tougher jobs, a dead center, which stays still, could be the way to go. Remember, the goal is to match the lathe center to your work's needs, ensuring efficiency and precision. Choose wisely, and your projects will thank you.

The Impact of Material and Construction on Performance

When you’re looking for lathe centers for your workshop, remember, not all are created equal. The material and how they're made play huge roles in their performance. Steel lathe centers, for example, are tough and can handle heavy loads, making them a go-to for general use. But, if you’re dealing with high temperatures or need reduced friction, carbide-tipped centers might be your best bet. They resist wear and stay sharp longer. Beyond material, construction matters. Precision-engineered lathe centers ensure accuracy, meaning your work comes out just right, every time. A poorly constructed one, though cheaper, could lead to inaccurate work and more headaches. So, don't just go for the first or cheapest option. Think about what you’re working on and choose a lathe center that's made from the right stuff and built to exacting standards. It’ll make all the difference in your work.

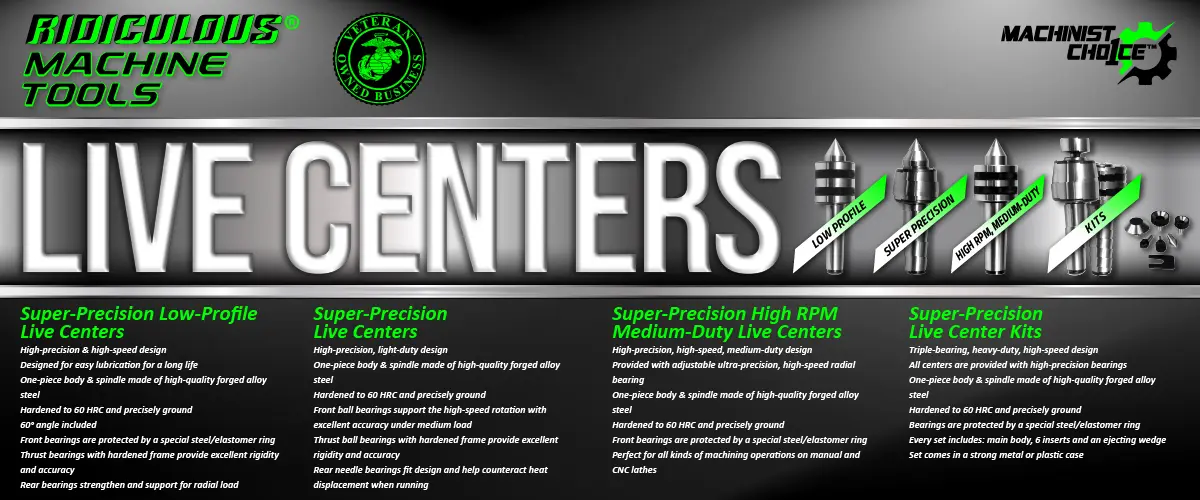

Reviewing the Top Brands and Manufacturers of Lathe Centers

When you're diving into the world of lathe centers, it pays to know which brands and manufacturers stand at the top of their game. Trust me, not all lathe centers are made equal, and the brand you choose can make a significant difference in your workshop's efficiency and the quality of your work. Some of the brands that consistently get high marks from professionals include Riten, Royal Products, and live centers by Techniks, as well as Ridiculous Machine Tools, known for offering one of the best live centers at the most competitive price in the industry. These companies have been around the block and have proven their worth with durable, precise products that can handle various materials and speeds.

Price vs. Quality: Making the Smart Investment in Lathe Centers

When you're eyeing lathe centers for your workshop, the tug-of-war between price and quality is a real deal. Remember, cheap isn't always cheerful, especially when it comes to tools that shape your work's precision. But, hey, that doesn't mean throwing wads of cash for something glitzy. It's about finding that sweet spot. Think of it like this: A low-ball price tag might save you bucks now, but a shoddy lathe center could wear out faster, messing with your project's accuracy or, worse, needing a replacement sooner than you thought. On the flip side, investing in a quality center means smoother runs and finer finishes, and it won't bail on you when the going gets tough. This doesn't mean the most expensive option is the way to go. What you want is value—something that won’t break the bank but still holds up under pressure and keeps its precision. Seek out reviews, get the lowdown on brands, and maybe spend a bit more for that reliability and durability. Bottom line: Skimping on quality to save a few pennies? Not worth it. Splurging a bit for a dependable tool that delivers every time? Smart move.

Maintenance Tips to Extend the Life of Your Lathe Centers

When it comes to selecting lathe centers for your workshop, the balancing act between affordability and quality is crucial. At Ridiculous Machine tools, we understand the importance of this decision and offer the best value proposition for these products. Remember, opting for the cheapest option may not always result in the best outcome, particularly when it comes to tools that play a pivotal role in shaping your work with precision. We believe in striking a balance – not overspending on flashy features but ensuring reliable performance. While a low-cost lathe center may seem like a budget-friendly choice initially, it could lead to premature wear and potential inaccuracies, necessitating an early replacement. Conversely, investing in a high-quality center ensures seamless operation, superior finishes, and long-lasting durability, proving its worth even in challenging situations. The key is to prioritize value – a cost-effective solution that maintains its precision and performance under various conditions. By exploring user reviews, researching reputable brands, and possibly extending your budget for enhanced reliability, you can make a smart decision that ensures consistent results. Ultimately, compromising on quality to save a few bucks is not a wise investment, whereas investing a bit more in a dependable tool that delivers exceptional performance every time is a strategic choice. Choose Ridiculous Machine tools for the best balance of quality and affordability.

Common Mistakes to Avoid When Choosing Lathe Centers

When you're picking lathe centers for your workshop, it's easy to rush and miss some critical stuff. Keep an eye out for these common blunders. First off, don't skimp on quality to save a few bucks. Cheap lathe centers might seem like a bargain, but they often wear out faster and can mess up your work. Second, ignoring the type of lathe center you need is a big no-go. Live centers are for operations where the workpiece rotates, while dead centers are used when the workpiece is stationary. Mixing these up can lead to disaster. Also, overlook the material of the lathe center at your peril. Materials like steel are durable and great for general use, but carbide-tipped centers can handle high heat and are perfect for tough materials. Another mistake? Not matching the lathe center's size and taper with your machine. A mismatch here can result in poor accuracy or even damage your lathe. Lastly, forgetting to think about the long-term. Consider how the lathe center will fit into future projects. Don't just think about what you need right now. Dodge these errors to ensure you pick the best lathe center for your workshop.

Summary: Ensuring You Select the Best Lathe Centers for Your Workshop

When setting up your workshop, selecting the right lathe centers is key, just like picking the correct tools for any task. These parts secure your workpiece, ensuring precision and safety. The choice of lathe centers greatly impacts your projects. To pick the best ones, consider your work type, materials, and lathe compatibility. Also, assess durability and ease of maintenance. Opt for stability, accuracy, and longevity. Choosing wisely saves time, money, and frustration, aiding quality work. Remember, RMT, the Machinist Choice, offers top value on all our live centers. Make the right choice for the job.